Frost is an industry leading manufacturer of high quality, durable material handling conveyors and conveyor components. Our products operate in numerous market segments including Automotive, Industrial, Bakery, Food Processing, Poultry, Furniture, Paper Mill, Aerospace and Packaging. For over 100 years, our commitment to using the best materials and employing skilled machinists and assemblers has enabled us to excel in delivering what customers want, when they want it.

Products

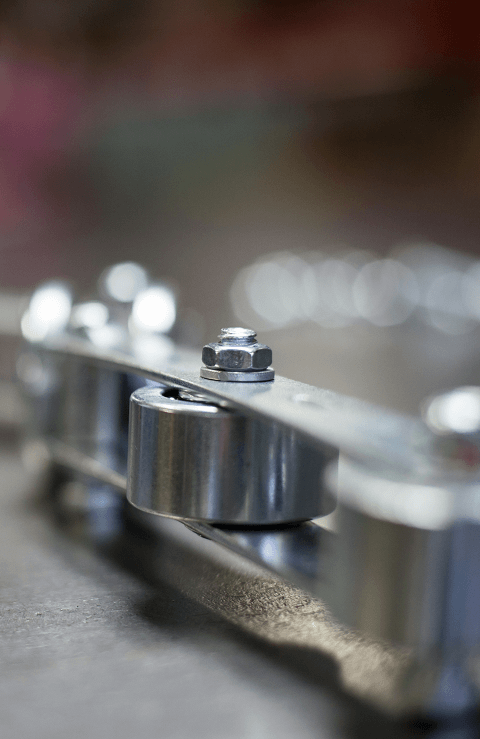

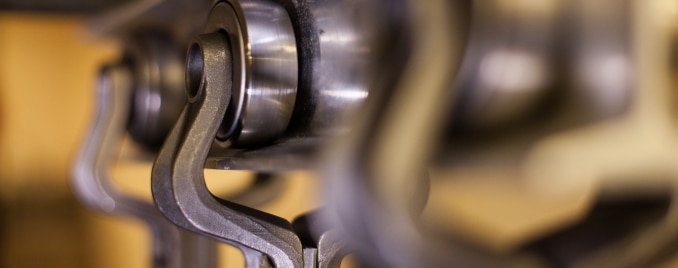

Our sales and engineering teams work closely with customers to provide a wide variety of solutions which include Overhead Chain & Trolley Conveyors, Enclosed Track Conveyors, OEM Compatible Free Trolleys (Overhead & Inverted), Hand Pushed Trolleys, Roller Turn Rollers, Special Wheels, Bearings, Attachments and Other Conveyor Accessories.

Applications

Frost offers engineered material handling conveyor systems, components and services that will meet your application’s specific requirements. Our goal is to help you increase productivity by designing the systems and components from start-to-finish. We have four plants with different capabilities across the state of Michigan, USA here to serve you.

Have a question?

Please fill out a brief form and we will get back to you shortly.